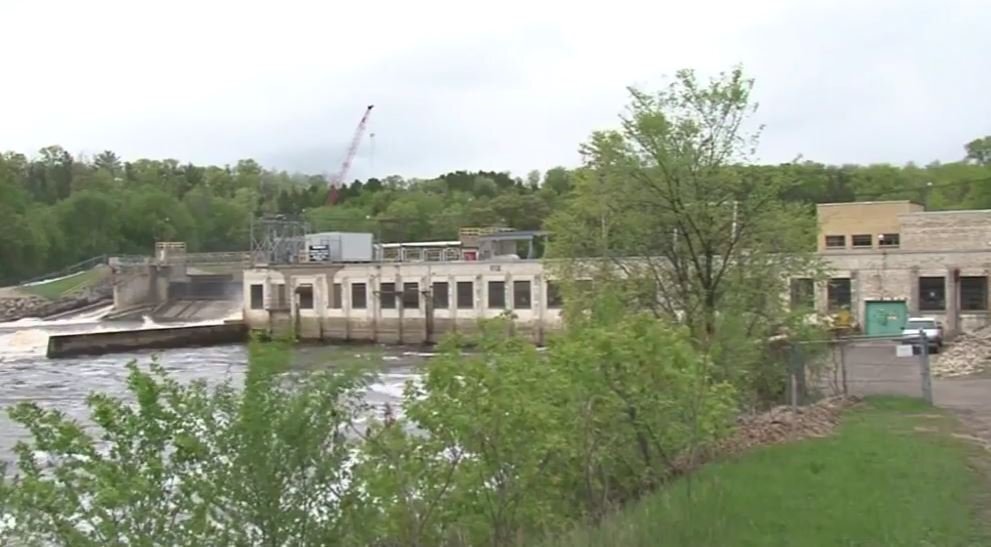

BRAINERD HYDROELECTRIC PLANT

This project included commercial hard hat diving services to meet OSHA diving standards. OSHA standards required a 4-man dive team to meet the minimum standards of the industry during penetration of the lower hydro dam. Additional sector scanning measurements were performed for a more detailed assessment.

DIVING SERVICES

Divers completed an inspection and as-built measurements for Gracon LLC project planning purposes and replacement of hydro-electric generation systems. The inspection areas included the upstream intake stop log opening and the downstream section of a single unit. The purpose of the inspection was to figure out what the downstream of the unit looks like so a bulkhead could be built to seal up the unit so it can be worked on in the dry. The inspection results and all measurements were given to Gracon and its engineers at the end of the diving process.

SECTOR SCANNING SERVICES

Sonar technician worked with divers to scan voids in the downstream unit to determine overall dimensions of the draft tube and the concrete outfall section. Sonar was placed by divers at different distances into the outfall section and draft tube and supported on a tripod for stability. Scanning images and measurements were captured and checked with diver measurements.